Laser paintbrush as a tool for modern art

Лазерные технологии, Научная библиотека, Новости науки и техники 23.04.2021 Комментарии к записи Laser paintbrush as a tool for modern art отключеныВадим Вейко, Ярослава Андреева, Луонг Ван Куонг, Дарья Лутошина, Дмитрий Поляков, Дмитрий Синев, Владимир Михайловский, Юрий Р. Колобов, Галина Одинцова, «Лазерная кисть как инструмент современного искусства», Optica 8 , 577-585 (2021 год)

Свет важен для искусства. Он позволяет нам видеть цвет и сам по себе может быть инструментом для создания уникальных произведений искусства и дизайна. Здесь мы демонстрируем, что лазер может быть многофункциональным и эффективным инструментом для создания шедевров, аналогичным процессу художника, создающего холст с помощью классических красок и кистей. Мы исследуем взаимодействие между сфокусированным лазерным излучением и металлическими поверхностями и анализируем оптические эффекты в тонких оксидных пленках для трех основных художественных операций: создание цвета, множественное изменение цвета и стирание, управляемое наносекундным лазером. Эти процессы возможны при нагревании материала выше точки испарения, и доказано, что они зависят от скорости охлаждения, как согласно экспериментальным, так и теоретическим результатам.

Abstract

Light is critical for art. It allows us to see color, and can itself be a tool for creating unique pieces of art and design. Here we demonstrate that a laser can be a multifunctional and effective tool for the creation of masterpieces, analogous to the process of an artist creating a canvas with classical paints and brushes. We investigate the interaction between focused laser irradiation and metallic surfaces and analyze the optical effects in thin oxide films for three main artistic operations: color making, multiple color changes, and erasing managed by a nanosecond laser. These processes are possible upon heating the material above the evaporation point and are proved to be dependent on the cooling rate, according to both experimental and theoretical results. Such an interference-based laser paintbrush could find applications in modern art and design.

1. INTRODUCTION

From the early days people have encoded messages by drawing primitive pictures and patterns on rocks, and they have created small drawings and toys to describe the world around them. Then, step by step, ancient art and painting were born. Gradually, the progress of tools and human thought led to a symbiosis of art and technology; one of the brightest examples is Leonardo da Vinci’s heritage. Nowadays, with the rapid development of technologies and industry, the evolution of contemporary art is taking place, and novel artistic techniques are being introduced by modern artists from all over the world.

The most common artistic materials are oil paints, watercolors, inks, pastel, charcoal, etc. Let us consider different ways of creating a colorful image without using any of these usual colorants. Obviously, different optical effects such as interference; diffraction; near-field, far-field, and nonlinear effects; collective resonances, and so on can act as effective tools for obtaining a color palette [1–15]. For instance, plasmonic nanostructures absorb and re-emit the light at the specific wavelengths due to localized surface plasmon resonance [5,6,16,17]. Also, various semiconductor or all-dielectric nanostructures possessing minimal losses in the visible spectrum produce color due to arising of magnetic and electric dipole resonances [9,18–20]. Color change is possible by manipulation of size, shape, and distribution of nanostructures, and a number of researches have already described various approaches, for example, chemical synthesis [1,21,22], lithography methods [2,11,12,19], focused ion beam milling [13], and laser-based fabrication [4,14,17,23,24]. Other groups of works [25–28] have described color creation on micro- and nanogratings by diffraction effects. But such diffraction patterns usually exhibit a certain color only when viewed from a predetermined angle. Another broad group of promising dye-free coloration techniques uses different coatings and interference films [1,28–31]. To apply a colorful picture on different materials, the method of colloidal ink jet imprinting has been recently developed [29,31]. The method is based on application of colloidal film with a given thickness. Despite the obvious pros of the discussed color printing methods (like bright colors and ability to control spectra with high accuracy), most of the mentioned techniques are still time-consuming, costly, and may appear unstable in the long run. Thus, they are applicable only for small-scale short-lived images. It is important to note that all the considered methods are nonreversible, which means it is still challenging to rewrite or erase the color if an artist makes a mistake or decides to change the original idea.

Laser oxidation of metals is known to be a promising way of controlled color creation, which offers fast, large-scale, and eco-friendly writing of colorful pictures. Local manipulation with colors is handled by precise tuning of an oxide thickness and chemical composition [30,32–37] as well as treatment environment [38,39]. Another work introduced the computational algorithms to provide good color image reproduction; moreover, the authors managed over seven different laser processing parameters to expand and systematize the color gamut on stainless steel [40]. On titanium surfaces different color palettes were also developed by several research groups [32,39]. We have recently demonstrated that such colors on titanium surface are extremely resistant to environmental and chemical impacts [41], and therefore a laser-induced picture is everlasting and does not require any special storage environment. All of these facts show the great potential of laser oxide-based coloration for industrial applications; nevertheless, the possibility of laser painting for art is still pending. To paint an authentic picture, one need not only be able to apply a color according to the template but also to change and manage colors up to their complete erasure. At the same time, mechanisms and principles that make change and erasure of the interference-based structural colors in air possible have not yet been investigated.

Our article presents for the first time to our knowledge the laser treatment as a paintbrush for creation the colorful images, or “paintings” on the titanium surface. We concentrate on different ways of creating an image following the conventional steps of an artist: making color strokes, changing the color, and erasing some fragments. Here we expand the opportunities of laser coloration by representing all these actions by fast laser writing on a titanium surface and describe the mechanisms behind this technique, including local laser heating, laser oxidation, and erasing of the oxide film. In order to investigate these processes, we perform detailed analysis of physical and chemical processes under laser irradiation based on experimental and numerical results. As opposed to previous works, we consider the process of laser heating above the metal evaporation temperature. Vaporization is then followed by metal oxidation at the cooling stage, and the resulting color forms during the temperature dropping. This oxidation regime makes it possible to either rewrite or erase colors by varying the cooling rate. We also consider the optical effects on oxide films depending on their thickness using the theory of wave propagation through a stratified semitransparent film on an opaque substrate. The possibility of rewriting or erasing colors in an airy atmosphere would take laser coloring to a new level, allowing not only reproduction of already known images from a template but also modification of an image during the drawing process according to the wishes of an artist. We believe that laser paintbrush technique will pave the way for creating a new kind of modern art and design.

2. MATERIALS AND METHODS

A. Laser Fabrication of Color Miniature Painting

A nanosecond ytterbium fiber laser system equipped with a two-axis galvanometric scanner was used to create color strokes as well as to erase and rewrite color. The laser miniature painting was drawn on a 1 mm thick titanium alloy (Ti6Al4V) polished plate, cleaned with ethanol before using. A F-theta lens ensured the uniform focalization of laser beam within the area of 110×110mm. A focused Gaussian beam with a spot diameter of 𝑑0=50µm scans the sample line by line, providing the defined overlap between two lines (for details see also [30]). During all the experiments pulse duration of 𝜏=100ns, laser intensity 𝐼=1.02⋅107W/cm2, repetition rate 𝑓=900kHz, and number of pulses along the 𝑦 axis 𝑁𝑦=1 remained the same, whereas the scanning speed 𝑉sc varied within the range of 100−1500mm/s to obtain different effects.

B. Numerical Simulation

Numerical simulations of the reflectance spectra were conducted based on a theory of wave propagation through a stratified semitransparent medium described in [42]. The modeling was carried out within the range of 300–1100 nm. Spectral values of the complex refractive indices 𝑛′𝑗=𝑛𝑗+𝑖𝑘𝑗 were taken in accordance with [43] for titanium alloy Ti6Al4V and [44–47] for titanium oxides TiO2 and Ti3O5. The temperature distribution was calculated by numerical finite-difference solving of the nonstationary nonlinear three-dimensional heat conduction equation with corresponding boundary and initial conditions. The heat capacity and heat conductivity of titanium temperature dependencies were taken from [48]. The reflection coefficient of Ti at wavelength 1.06 µm was considered equal to 0.56 [49]. Latent heat of melting 𝐿𝑚=1.3⋅103J/cm3 and latent heat of evaporation 𝐿𝑒𝜈=4⋅104J/cm3 were taken from [48]; 𝑣𝑒𝜈 is the evaporation rate that was considered in the Hertz–Knudsen approximation (see for example [50]).

C. Measurements

To examine microscopic appearance of color strokes, a Zeiss Axio Imager A1 m optical microscope was utilized in a reflection configuration. To measure reflectance spectra of the laser irradiated areas, we used the SF-56 spectrometer with an unpolarized light source. The atomic force microscope Nanoeducator was used to investigate surface topology after laser irradiation. To investigate the composition and crystalline phase of the color strokes, transmission electron microscopy (TEM) and the transmission scanning electron microscopy (SEM) were used. The Tecnai G2 F20 microscope with field emission equipped with an EDAX c microanalysis system and silicon drift detector was utilized. Ion thinning by a focused ion beam (FIB) on an Zeiss Auriga SEM was utilized for the preparation of thin foils (lamellas) for TEM. The detailed description of the lamella preparation process is presented in Supplement 1 (section “Sample Preparation for TEM”). As a result, square samples of approximately 3µm2 with a thickness of approximately 100 nm were obtained.

3. RESULTS

A. Concept and Design

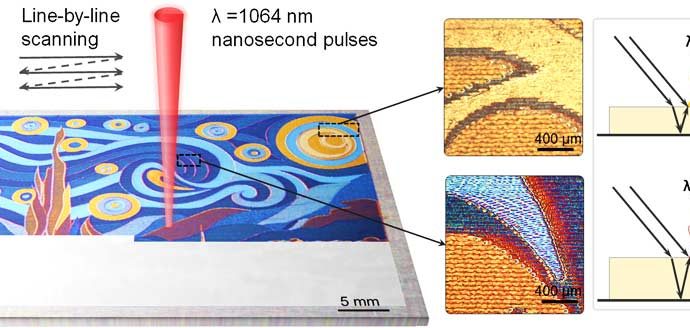

Three basic techniques were developed for laser painting: (i) creating colors or individual color strokes, (ii) color mixture or changing one color to another, and (iii) color erasing. We call these three operations altogether the “laser paintbrush.” The schematic of the laser paintbrush technique is shown in Fig. 1. Colors were formed, changed, and erased on the titanium surface by single step laser scanning (see Section 2, Materials and Methods, for details). A laser beam scanned the surface line by line with different scanning speeds. In general, this process is rather fast (average productivity is 1.1−12.5cm2 per min, depending on the color) and does not require any additional pretreatment, chemicals, or special environment.

Fig. 1. Schematics of laser paintbrush and microimages of color strokes.

Fig. 2. Principle of color laser paintbrush. (a) Applying of color strokes: schematics of the process and photo of the color palette for titanium: laser intensity 𝐼=1.02⋅107W/cm2I=1.02⋅107W/cm2, and scanning speed decreases from 500 to 100mm/s100mm/s with the step of 50mm/s50mm/s for colors Ti1Ti1 to Ti9Ti9,

Fig. 3. Color maps for laser painting, color change, and erasing for 𝐼=1.02⋅107W/cm2I=1.02⋅107W/cm2. (a) Color palette of the laser paintbrush. The map represents color dependencies on different scanning speed: the single-step coloration regime on a bare titanium (coloring zone), the change of eight initial colors for other ones (color change zone), complete erasing of colors (erasing zone). (b) Multiple rewriting of the color circle: colors are changed in a consequence, the result after initial writing (first pass), and rewriting (second and third passes).

Полное содержание статьи: https://www.osapublishing.org/optica/fulltext.cfm?uri=optica-8-5-577&id=450302